Understanding Roof Ventilators

Overview of Roof Ventilation – The importance of proper roof ventilation in building health and energy efficiency

Proper roof ventilation is essential for maintaining a healthy building environment. Surprisingly, up to 25% of a building’s energy loss can be traced back to inadequate ventilation. A roof ventilator mechanism plays a crucial role in regulating airflow, preventing moisture buildup, and reducing indoor temperatures. When airflow is optimized, it helps extend the lifespan of roofing materials and prevents costly damage caused by mold and rust.

Understanding the function of a roof ventilator mechanism is key to appreciating its importance. It works by drawing out hot, stale air from within the building while allowing cooler air to enter. This continuous exchange maintains a balanced indoor climate. In South Africa’s climate, where temperatures can soar during summer, effective roof ventilation becomes even more vital for energy efficiency and comfort.

- Reduces cooling costs by removing excess heat

- Prevents moisture-related damage

- Enhances overall building longevity

Types of Roof Ventilators – Different categories such as turbine, static, powered, and solar roof ventilators

Understanding the different types of roof ventilators reveals how their unique mechanisms address specific ventilation needs. Each category operates on distinct principles but shares the common goal of optimizing airflow and safeguarding building integrity. For instance, turbine roof ventilators utilize wind energy to spin and exhaust hot, stale air, making them highly effective in breezy South African climates. Static roof ventilators, on the other hand, rely on natural convection, allowing warm air to escape without moving parts, offering a silent, low-maintenance solution.

Powered roof ventilators introduce an electric motor into the mix, providing consistent airflow regardless of external conditions. These are ideal in settings where airflow needs to be meticulously controlled. Solar roof ventilators harness the abundant South African sunshine, converting sunlight into energy to operate. They embody eco-friendly innovation, reducing reliance on electricity while ensuring continuous ventilation.

- Wind-driven turbine ventilators

- Static vents for passive airflow

- Electric-powered ventilators for precise control

- Solar-powered units for sustainable operation

Each type of roof ventilator mechanism offers distinct advantages, making it essential to select the right one for specific building requirements and climate conditions. This choice directly impacts the efficiency of roof ventilation and the longevity of the roofing system.

Components of a Roof Ventilator – Key parts including the motor, blades, casing, and flashing

At the heart of every effective roof ventilator mechanism lies a symphony of carefully engineered components, each playing a vital role in orchestrating optimal airflow. The motor, often the silent powerhouse, drives the blades or fans, transforming electrical energy into motion with precision and grace. Without it, the entire system would stand still, lost in the stillness of stagnant air.

The blades themselves are crafted to catch the wind or spin with mechanical finesse—whether turbine blades harness the wind’s invisible force or the blades in powered units rely on motor torque. Encasing these moving parts is a sturdy casing, designed not only for durability but also to streamline airflow, reducing resistance and noise. Properly installed flashing ensures that the roof ventilator mechanism remains sealed against the elements, protecting internal parts from rain or debris while maintaining seamless integration with the roofing surface.

Understanding these key parts—motor, blades, casing, and flashing—equips us with the knowledge to select the perfect roof ventilator mechanism tailored to South Africa’s diverse climate. Each component’s role is crucial in ensuring the longevity of the roofing system while promoting efficient, eco-friendly ventilation that keeps buildings cool and safe under the blazing sun.

How Roof Ventilator Mechanisms Work

Principles of Operation – Explaining aerodynamic and mechanical processes behind ventilation

At the core of every effective roof ventilator mechanism lies a fascinating dance between aerodynamic principles and mechanical ingenuity. When designed with precision, these systems harness natural airflow patterns to foster continuous ventilation, often requiring no external power. The aerodynamic process hinges on the creation of pressure differentials—warm, stale air rises naturally, drawing cooler, fresh air in through other openings. This subtle yet relentless movement sustains a cycle that keeps the interior environment invigorated and free from excess moisture or heat buildup.

Meanwhile, the mechanical components of a roof ventilator mechanism work in harmony to amplify this natural flow. For instance, rotating blades—whether turbine or powered—act as catalysts, accelerating airflow through centrifugal or aerodynamic forces. The casing and flashing serve not only as protective barriers but also as channels that guide air efficiently, minimizing turbulence. In some cases, smartly engineered mechanisms like solar-powered blades or static vents enhance the natural cycle, transforming passive ventilation into an active, energy-efficient process. Ultimately, understanding these intricate processes reveals how a roof ventilator mechanism is a marvel of engineering, blending physics with functionality to maintain optimal building health.

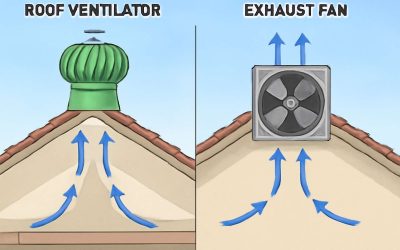

Passive vs. Powered Systems – Differences between natural airflow mechanisms and motor-driven systems

In the world of roof ventilator mechanisms, not all systems are created equal—some rely purely on Mother Nature’s whimsy, while others have a bit more muscle behind them. Passive ventilation, for instance, leverages natural airflow, using aerodynamic principles to keep the air fresh without a single watt of power. Warm air rises naturally, creating pressure differentials that draw cooler, fresher air in through other openings, maintaining a steady, silent cycle. It’s like the building’s own breath of fresh air, no batteries required.

On the flip side, powered systems introduce an energetic twist—think turbines and electric fans—amplifying that natural airflow with mechanical force. These motor-driven roof ventilator mechanisms can be classified into two main types:

- centrifugal fans

- axial fans

both designed to accelerate airflow, even when natural currents are sluggish. Solar-powered blades add a dash of eco-friendly flair, transforming passive airflow into an active, energy-efficient dance. Whether passive or powered, understanding how each system works helps ensure your building stays cool, dry, and free of unwanted moisture—no sweat, literally!

Role of Wind and Temperature – Influence of environmental factors on ventilator performance

Environmental factors such as wind and temperature play a starring role in the performance of a roof ventilator mechanism. When the wind howls, it doesn’t just ruffle feathers – it can significantly boost natural airflow through a building’s roof vents. The pressure differences created by gusts help draw stale, hot air out and usher in a refreshing breeze, even in the absence of mechanical assistance.

Temperature, on the other hand, acts as the silent puppeteer pulling the strings behind ventilation efficiency. Warm air naturally rises, creating a buoyant effect that pulls cooler air in from outside. This process, known as stack effect, is the cornerstone of passive ventilation systems. The more dramatic the temperature differential, the more vigorous the airflow—turning your roof into a natural exhaust fan that operates quietly and effortlessly.

In certain conditions, these environmental influences can be unpredictable, which is where a well-designed roof ventilator mechanism shines. It adapts to fluctuating wind speeds and temperature shifts, ensuring your building remains cool and moisture-free. Think of it as the building’s own weather whisperer, harnessing Mother Nature’s whims to keep indoor air fresh without breaking a sweat.

Design Features of Effective Roof Ventilators

Blade Design and Materials – Optimal shapes and durable materials for efficient airflow

Within the realm of roof ventilator mechanisms, the design of blades stands as the silent hero, orchestrating the dance of airflow with grace and precision. Optimal blade shapes—curved or angled—are crafted to harness the wind’s whisper, transforming it into a powerful force that draws stale air upward and out of the building. These shapes are not chosen at random; they are the culmination of aerodynamic mastery, ensuring maximum efficiency with minimal resistance.

Complementing the blade design are the materials—robust, weather-resistant substances that withstand South Africa’s diverse climate. Aluminum, galvanized steel, and UV-stabilized plastics are popular choices, each offering durability and longevity. These materials are not only resilient but also lightweight, allowing the roof ventilator mechanism to operate smoothly, reducing wear and tear over time. When combined, the optimal shapes and high-quality materials create a symphony of airflow, vital for maintaining healthy, energy-efficient buildings.

Motor Technology – Types of motors used, including solar and electric options

At the heart of a truly effective roof ventilator mechanism lies the sophistication of its motor technology. It is the unseen force driving the seamless exchange of stale indoor air with revitalizing breezes, ensuring the longevity of building integrity. In the realm of roof ventilation, the choice between solar and electric motors is more than a matter of convenience; it shapes the entire dynamic of airflow efficiency and energy consumption.

Solar-powered roof ventilators harness the sun’s relentless energy, transforming it into a sustainable force that operates silently and independently of electrical sources. These systems are especially advantageous in South Africa’s sunny climate, reducing operational costs while promoting eco-friendly building practices. Conversely, electric motors—robust, dependable, and variable—offer precise control and higher airflow rates, making them ideal for larger structures or environments demanding meticulous ventilation management.

Within the design of a roof ventilator mechanism, the motor’s role is complemented by features like variable speed settings and smart controls, which adapt airflow based on environmental conditions. Some systems incorporate

- brushless DC motors

- AC asynchronous motors

each selected for their durability and efficiency. The interplay of these motor technologies ensures the ventilator operates smoothly, with minimal wear, and responds dynamically to changing wind and temperature conditions—factors that heavily influence performance and longevity.

Weather Resistance and Durability – Design considerations for harsh weather conditions

In the battle against relentless weather, a roof ventilator mechanism must stand resilient, transforming fierce elements into invisible allies. Weather resistance isn’t merely an afterthought; it is the cornerstone of an effective design. Constructed from corrosion-resistant materials like galvanized steel or UV-stabilized plastics, these mechanisms endure South Africa’s scorching sun, heavy rains, and gusty winds without faltering. The casing, often reinforced with weatherproof seals, guards the delicate internal components against moisture and debris, ensuring longevity that outlasts seasons.

Durability is woven into the very fabric of an effective roof ventilator mechanism. Features such as vibration-dampening mounts and reinforced blades prevent wear and tear, while smart design choices—like aerodynamic shapes—reduce wind resistance and noise. For rooftops exposed to harsh conditions, selecting a system with built-in weatherproofing guarantees optimal airflow while safeguarding vital parts. The combination of robust construction and thoughtful engineering makes these ventilators not just functional, but stalwart guardians of building integrity against South Africa’s unpredictable climate.

Installation and Maintenance of Roof Ventilator Mechanisms

Proper Installation Techniques – Guidelines for secure and effective setup

Amidst the shadows of a weathered roof, the installation of a roof ventilator mechanism demands precision and reverence. It is not merely about securing a device; it’s about harmonizing with the elemental forces that govern airflow and weathered resilience. Proper installation techniques ensure that the silent sentinel atop your structure functions flawlessly, guarding against the chaos of heat and humidity that threaten the sanctity of your space.

To achieve this, meticulous attention must be paid to the placement of flashing and seals, preventing the ingress of moisture and wind-driven debris. A well-secured roof ventilator mechanism relies on a foundation that withstands the tempest’s fury, whether it’s the relentless South African sun or fierce storms. For optimal efficacy, consider the following steps:

- Ensure the opening aligns precisely with the ventilator’s casing.

- Use weather-resistant fasteners that will not succumb to corrosion over time.

- Seal all joints with high-quality, durable flashing to prevent leaks.

Maintenance is equally vital—regular inspections for corrosion, debris buildup, and mechanical wear keep the mechanism functioning as a guardian of airflow. A neglected roof ventilator mechanism becomes a silent threat, its purpose lost amid rust and dirt. Embrace routine upkeep, and your roof’s silent sentinel will serve faithfully through the ages, whispering tales of airflow mastery in the shadows of the sky.

Maintenance Procedures – Routine checks, cleaning, and troubleshooting tips

The longevity and efficiency of a roof ventilator mechanism hinge on diligent maintenance and attentive installation. Over time, dust, debris, and corrosion can compromise its performance, transforming a vital airflow guardian into a potential liability. Regular inspections are essential—not just to spot rust but to ensure all components are functioning harmoniously. In the unpredictable climate of South Africa, where storms and intense sun are common, a well-maintained roof ventilator mechanism can be the difference between a cool, ventilated space and one overwhelmed by heat and humidity.

Cleaning should be a routine part of upkeep. Remove any accumulated debris from blades and vents, and check for signs of mechanical wear. Troubleshooting often involves inspecting the motor, ensuring it’s free of dust and operating smoothly. If noise or sluggishness occurs, it could signal a failing component or the need for lubrication. To streamline this process, consider implementing a simple maintenance schedule, such as:

- Visual inspection of the entire roof ventilator mechanism for corrosion or damage.

- Cleaning blades and vents to optimize airflow.

- Testing the motor’s operation and listening for unusual noises.

Using weather-resistant fasteners and sealing all joints with high-quality flashing during installation provides a resilient foundation that withstands South Africa’s fierce weather. Troubleshooting tips also encourage checking for loose connections or obstructed airflow pathways, which can diminish efficiency. When maintenance becomes a routine, your roof’s silent sentinel remains vigilant, ensuring continuous airflow and protecting the structural integrity of your building against the relentless forces of nature.

Common Issues and Repairs – Identifying and resolving typical mechanical problems

A malfunctioning roof ventilator mechanism can turn a building’s best defense against heat and humidity into a major liability. Common issues such as worn-out bearings, broken blades, or loose connections are often overlooked until airflow diminishes or noise levels surge. Identifying these problems early is crucial for maintaining optimal ventilation and preventing costly repairs.

Troubleshooting typically begins with a visual inspection—checking for rust, corrosion, or physical damage. Mechanical wear can be subtle, so listening for unusual noises or sluggish operation can provide valuable clues. If the motor appears to be struggling, lubricating moving parts or replacing faulty components often restores performance. Sometimes, obstructed airflow pathways caused by debris or bird nests can impede efficiency, so routine cleaning and inspection are essential.

In South Africa’s unpredictable climate, ensuring your roof ventilator mechanism is resilient involves using weather-resistant fasteners and sealing joints with high-quality flashing. When issues arise, a systematic approach—such as following an ordered list for repairs—can streamline the process and extend the lifespan of your ventilation system.

Advantages of Modern Roof Ventilator Mechanisms

Energy Efficiency Benefits – Reducing cooling costs and enhancing indoor air quality

A modern roof ventilator mechanism offers more than just airflow; it’s a game-changer for energy efficiency. By effectively expelling hot air from the attic, these systems reduce the burden on air conditioning units, leading to noticeably lower cooling costs. This means homeowners and business owners in South Africa can enjoy a cooler indoor environment without skyrocketing energy bills.

Thanks to advancements in design and technology, roof ventilator mechanisms now operate with minimal energy input, often harnessing wind and temperature differentials. This passive approach maximizes airflow while conserving power. The result? Improved indoor air quality, less mold buildup, and a longer lifespan for roofing materials.

Investing in a high-quality roof ventilator mechanism not only boosts energy savings but also enhances the overall durability of the building. These systems are built to withstand harsh weather, ensuring reliable performance year-round.

Environmental Impact – Use of sustainable and renewable energy sources like solar power

In the quest for a greener, more sustainable future, modern roof ventilator mechanisms stand as silent sentinels—harnessing the boundless energy of the sun and wind to breathe life into our buildings. These innovative systems are not merely ventilators; they are embodiments of environmental stewardship, quietly reducing reliance on electricity and diminishing carbon footprints. By utilizing renewable energy sources like solar power, a roof ventilator mechanism transforms from a simple airflow device into a beacon of eco-conscious design.

With the advent of solar-powered roof ventilators, the potential for harnessing natural forces has reached new heights. Imagine a device that operates tirelessly, powered solely by the sun’s relentless energy, with no need for electric motors or external power. Such systems exemplify sustainable ingenuity, seamlessly integrating into the building’s fabric while leaving a minimal environmental imprint.

Furthermore, these eco-friendly innovations contribute to reducing greenhouse gas emissions and conserving precious natural resources. The use of sustainable materials and renewable energy sources ensures that each roof ventilator mechanism not only enhances building durability but also champions the cause of environmental preservation. In South Africa, where the sun’s embrace is generous and wind patterns favorable, deploying solar and wind-driven roof ventilators becomes a natural choice—merging technological excellence with ecological responsibility.

Improved Building Longevity – Preventing moisture buildup and structural damage

Modern roof ventilator mechanisms offer more than just airflow—they are crucial for enhancing building longevity. By preventing moisture buildup, these systems protect structural elements from rot, mold, and corrosion. Proper ventilation ensures that warm, moist air escapes efficiently, reducing the risk of dampness that can weaken roof integrity over time.

In addition to safeguarding the structure, an effective roof ventilator mechanism maintains a balanced indoor environment. It helps regulate temperature and humidity levels, which can otherwise cause materials to expand, contract, and deteriorate prematurely. This proactive approach extends the lifespan of roofing materials and the overall building envelope.

Some roof ventilator mechanisms incorporate innovative features, such as aerodynamic blade design and durable materials, to maximize performance even in harsh South African weather. Whether wind-driven or solar-powered, these systems operate seamlessly, providing continuous protection without increasing energy costs. Their durability makes them an investment that pays dividends in long-term building health.

Innovations and Future Trends in Roof Ventilator Mechanisms

Smart Ventilation Technologies – Automation and sensor-based controls

Innovations in roof ventilator mechanism technology are reshaping the future of building ventilation, particularly in regions like South Africa where climate variability is a constant challenge. Smart ventilation technologies now harness automation and sensor-based controls, dramatically enhancing efficiency and responsiveness. These systems can detect temperature fluctuations, humidity levels, and airflow needs in real-time, adjusting operation accordingly without human intervention. This not only optimizes energy use but also prolongs the lifespan of the roof ventilator mechanism.

One of the most exciting developments is the integration of renewable energy sources, especially solar power, into roof ventilator mechanisms. Solar-powered ventilators are gaining popularity for their sustainability and cost savings, reducing reliance on electrical grids. Moreover, the evolution of blade design and advanced materials means these systems can withstand harsh weather conditions, ensuring durability and consistent performance. As technology continues to evolve, these innovations promise a future where roof ventilation is smarter, more sustainable, and more efficient than ever before.

Integration with Building Management Systems – Enhancing performance through advanced controls

Innovations in roof ventilator mechanism technology are revolutionizing building management across South Africa’s diverse climate zones. The integration of advanced controls with Building Management Systems (BMS) enables real-time optimization of ventilation performance. Modern systems can seamlessly communicate with BMS to adjust airflow based on temperature, humidity, and occupancy, ensuring a balance between energy efficiency and indoor comfort.

One notable future trend is the deployment of smart control algorithms that leverage data analytics and machine learning. These systems can predict environmental changes and automatically fine-tune the roof ventilator mechanism, reducing unnecessary energy consumption. Incorporating renewable energy sources, such as solar power, further enhances sustainability. Solar-powered roof ventilator mechanisms are becoming a popular choice in South Africa, where sunlight is abundant and energy savings are critical.

Furthermore, the evolution of blade design and high-grade materials enhances durability, allowing these systems to withstand harsh weather conditions common in the region. By embracing these innovations, building owners can achieve smarter, more resilient ventilation solutions that contribute to long-term operational efficiency and environmental responsibility.

Emerging Materials and Designs – Next-generation materials for durability and efficiency

As the quest for sustainable and resilient building solutions intensifies across South Africa, the evolution of roof ventilator mechanisms takes center stage. Cutting-edge materials are redefining what durability and efficiency truly mean in the realm of ventilation technology. Imagine blades crafted from high-grade composites that resist corrosion, extreme weather, and UV degradation—these innovations ensure that roof ventilator mechanisms remain steadfast even amidst South Africa’s unpredictable climate zones.

Next-generation designs harness aerodynamic principles with refined shapes that optimize airflow, reducing energy consumption while maximizing ventilation. Manufacturers are experimenting with innovative materials like reinforced polymers and lightweight alloys, which not only enhance durability but also contribute to easier installation and maintenance. These advancements herald a new era where roof ventilator mechanisms are more than just functional—they are feats of engineering artistry that withstand the test of time.

Incorporating renewable energy sources such as solar power into the design of roof ventilator mechanisms is transforming the industry. Solar-powered systems eliminate reliance on grid electricity, making them an ideal choice for remote or off-grid locations. As technology progresses, the integration of smart sensors and adaptive blade mechanisms promises an era where ventilation is seamlessly optimized based on environmental conditions. The future of roof ventilator mechanisms is undeniably bright, driven by innovations that blend resilience, sustainability, and sophistication.

0 Comments