Understanding Roof Vent Termination

What is Roof Vent Termination?

Imagine a perfectly crafted piece of architecture, where even the smallest detail plays a role in the grander symphony of home efficiency. In the world of roofing, that detail is none other than the roof vent termination. This unobtrusive component serves as the final act in the venting process, ensuring that air escapes smoothly without inviting trouble—think leaks or unwelcome pests. A well-designed roof vent termination isn’t just about aesthetics; it’s about safeguarding your home’s integrity while maintaining optimal airflow.

What exactly is roof vent termination? Essentially, it’s the cap or cover that sits atop your roof vent pipe, sealing the opening while allowing air to vent out. Its primary function is to prevent debris, water, and small animals from infiltrating the vent system—an ongoing battle between nature and home comfort. Achieving proper roof vent termination involves more than just placing a cover; it requires careful consideration of weather resistance, ventilation efficiency, and compliance with building standards.

In fact, the choice of roof vent termination can influence your entire roofing system’s longevity. An effective termination will:

- Promote smooth airflow, preventing moisture buildup

- Protect against water infiltration during storms

- Avoid blockages caused by debris or nesting animals

Thus, a seemingly modest detail holds the power to dramatically affect your home’s ventilation health and overall durability. When it comes to roof vent termination, attention to detail isn’t just recommended—it’s essential for a roof that stands the test of time and weather!

Importance of Proper Vent Termination

In the intricate dance of home maintenance, the significance of a properly executed roof vent termination cannot be overstated. It’s more than just a cap; it’s the guardian of your roof’s health, silently defending against the relentless forces of nature. Proper vent termination ensures that airflow remains unobstructed, preventing moisture from lingering where it shouldn’t—an invisible threat that can compromise the integrity of your roofing system over time.

Without an effective roof vent termination, debris, water, and pests can infiltrate, causing blockages or damage that may lead to costly repairs. To truly safeguard your home, it’s vital to understand the role of each component involved in the venting process. When selecting a roof vent termination, consider factors such as weather resistance, ease of maintenance, and compatibility with your roofing materials, ensuring the longevity of your ventilation system and overall home durability.

Types of Roof Vents and Their Terminations

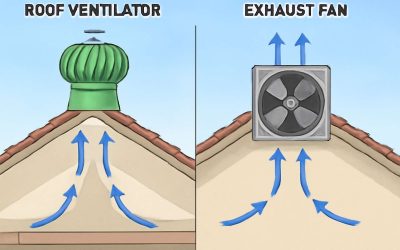

Understanding the different types of roof vents and their respective terminations is essential for maintaining an effective ventilation system. Roof vent termination varies depending on the vent style, the roofing material, and the climate conditions. For instance, static vents, ridge vents, and turbine vents each require specific termination methods to ensure optimal airflow and protection against the elements. Properly chosen and installed roof vent termination plays a crucial role in preventing moisture buildup and ensuring long-term durability.

Some common types of roof vent terminations include mesh screens, flashing collars, and weather-resistant caps. These components serve to prevent debris, pests, and water infiltration while allowing air to flow freely. To simplify the selection process, here are a few key considerations:

- Weather resistance: Ensuring the termination can withstand harsh weather conditions is vital.

- Compatibility: It must match the specific roof vent type and roofing material.

- Maintenance ease: Opt for designs that are easy to inspect and clean over time.

Choosing the right roof vent termination is more than just a matter of convenience—it’s an essential part of safeguarding your home’s ventilation system and overall roof integrity. With numerous options available, understanding the nuances of each can save you from costly repairs down the line!

Types of Roof Vent Termination Devices

Vent Caps

Among the myriad components that safeguard a building’s integrity, the roof vent termination device stands as a silent sentinel. Vent caps, a common form of roof vent termination, serve both aesthetic and functional purposes—protecting against the intrusion of debris and unwanted pests while allowing airflow to circulate freely. Their design can vary from simple, utilitarian covers to more ornate, custom-made fixtures that complement the architectural elegance of a structure.

Understanding the different types of roof vent termination devices is vital for ensuring longevity and optimal performance. Vent caps, for instance, come in various shapes—domed, louvered, or screened—each suited to specific needs and environmental conditions. An effective roof vent termination not only prevents water ingress, which could lead to costly damage, but also maintains the natural draft essential for proper ventilation. When selecting a vent cap, consider factors such as material durability, ease of maintenance, and compatibility with existing roofing materials.

Here are some common types of roof vent termination devices:

- Standard vent caps with screen protection

- Louvered vent caps designed for enhanced airflow

- Flanged vent caps that offer superior water resistance

Each variation plays a crucial role in the intricate dance of airflow, moisture control, and structural integrity. The choice of roof vent termination device can significantly influence the longevity of the roofing system, making it an essential consideration for homeowners and professionals alike. After all, a well-chosen vent cap is not just a functional necessity but a subtle nod to the artistry of craftsmanship—a testament to the enduring pursuit of perfection in architecture.

Flashing and Flashing Kits

In the labyrinth of roof ventilation, flashing and flashing kits serve as the unsung heroes, forging an impenetrable barrier against the relentless assault of water ingress. These components are meticulously engineered to conform seamlessly to the contours of the roof, ensuring that every vent termination remains resilient under the weight of storms and the passage of time. The beauty of flashing lies in its ability to create a waterproof sanctuary around the vent, safeguarding the structural integrity of the building with subtle sophistication.

When selecting flashing for roof vent termination, it’s vital to consider materials such as aluminium, stainless steel, or copper—each bringing its own blend of durability and aesthetic appeal. Proper installation is a delicate dance, one that requires precision and an understanding of how flashing integrates with various roofing materials. The deployment of flashing kits, often inclusive of sealants and fastening hardware, simplifies this process, providing a comprehensive solution that marries form and function.

- Assess the specific environmental conditions and select a flashing type that resists corrosion and extreme weather.

- Ensure the flashing overlaps appropriately with the roofing material to prevent water seepage at the seams.

- Combine flashing with a compatible roof vent termination device for an airtight, weatherproof seal.

Ultimately, the synergy between flashing and roof vent termination forms the cornerstone of a durable, efficient ventilation system. It transforms a mere component into an architectural safeguard, embodying the silent artistry that underpins enduring craftsmanship and meticulous design. In this dance of materials and precision, every detail matters—each element a testament to resilience and aesthetic harmony.

Cap and Screen Combos

Among the diverse array of roof vent termination devices, cap and screen combinations stand as guardians of the attic’s delicate sanctuary. These ingeniously designed components marry form and function, creating a formidable barrier against the ingress of debris, pests, and water. Their aesthetic simplicity conceals a profound purpose — to ensure that ventilation remains unobstructed, yet impervious to the chaos of the outside world.

The elegance of a cap and screen combo lies in its dual role: the cap provides a sturdy, weather-resistant crown atop the vent, while the screen invites in fresh air, thwarting unwelcome intruders. When selecting a roof vent termination device, consider the environment’s temperament — whether it’s the salty whispers of coastal air or the relentless assault of winter storms — and choose a design that withstands the test of time.

In the symphony of roof maintenance, the right combination of cap and screen not only enhances the efficiency of your ventilation system but also elevates the building’s aesthetic harmony. It is a subtle, yet vital, element in the grand tapestry of roof ventilation — a testament to craftsmanship and resilience.

Specialized Vent Terminals

Among the myriad options for roof vent termination, specialized vent terminals stand out as the guardians of airflow and protection. These devices are designed with precision, often resembling miniature sculptures that serve a vital purpose. Their unique shapes and materials ensure that ventilation pathways remain open and efficient while shielding the system from environmental intruders. Whether crafted from durable metals or weather-resistant plastics, these terminals are essential in maintaining the longevity of your roof’s ventilation system.

For those seeking tailored solutions, there are various types of roof vent termination devices, each suited to specific needs. Some are designed to optimise airflow in high-wind zones, while others focus on pest resistance and water diversion. The selection process can be simplified by understanding the environment’s challenges and the specific demands of your building’s architecture.

- High-wind vent caps

- Corrosion-resistant terminals

- Bird-proofing mesh inserts

These specialised vent terminals don’t just serve a functional purpose—they contribute to the aesthetic harmony of the structure. A well-chosen roof vent termination can seamlessly blend with the roofline, turning a utilitarian element into a finishing flourish that enhances the building’s visual appeal. Their role in the grand design underscores the importance of selecting the right device for optimal performance and durability in your roof ventilation system.

Materials Used in Roof Vent Termination

Metal (Aluminum, Copper, Steel)

When it comes to roof vent termination, selecting the right material isn’t just a matter of aesthetics—it’s about durability, performance, and resisting the relentless assault of weather. Metal options such as aluminum, copper, and steel have long been favoured for their resilience and timeless appeal. Aluminum, lightweight and corrosion-resistant, offers a budget-friendly solution that doesn’t compromise on longevity. Copper, with its distinctive hue and natural patina, lends a touch of elegance while boasting exceptional durability. Steel, often galvanised, provides robust protection against impact and rust, making it ideal for harsher climates.

Each material has its own unique strengths, shaping the character of your roof vent termination. For example, copper’s natural antimicrobial properties and ageing process can turn a simple vent into a statement piece. Steel, on the other hand, is often the go-to for commercial buildings where strength is paramount. Whichever choice you make, ensuring that the roof vent termination is crafted from quality metal guarantees a seamless blend of function and style, standing firm against the elements for years to come.

Plastic and PVC

While metal options often steal the spotlight, plastics like PVC and other synthetic materials have become increasingly popular in the realm of roof vent termination. Their affordability and ease of installation make them especially appealing for residential projects where budget-conscious choices are essential. PVC, in particular, is renowned for its resistance to weathering and chemical degradation, ensuring your roof vent termination remains intact for years to come.

Moreover, plastic vent caps and flashing components are lightweight yet durable, offering an efficient alternative to traditional metal. They’re less prone to corrosion, which is a crucial advantage in damp or coastal environments. For those seeking a seamless look, plastic options can be moulded into various shapes and sizes, fitting perfectly with the architectural style of your home or commercial building.

In some cases, a combination of materials can be used to achieve optimal performance and aesthetics. For example, a PVC vent cap paired with a metal flashing kit creates a robust barrier against the elements, ensuring the longevity of your roof vent termination. As technology advances, plastic and PVC solutions continue to evolve, offering homeowners and contractors a versatile, cost-effective alternative that doesn’t compromise on durability.

Rubber and Sealants

Rubber and sealants are the silent guardians of an effective roof vent termination, ensuring that no leak or gust of wind can breach the fortress of your roof’s integrity. These materials provide the essential flexibility and waterproofing needed to seal gaps around vents, preventing moisture infiltration and mould growth. Their adhesive qualities create a seamless barrier, moulded meticulously to fit the unique contours of each vent, transforming an ordinary roof into a masterpiece of protection.

Among the most trusted sealants used in roof vent termination are butyl-based compounds and high-quality silicone. They adhere tenaciously to diverse surfaces, resisting weathering, UV rays, and thermal expansion. For added durability, some professionals opt for specialised rubber gaskets or flashing strips, which act as a secondary line of defence, moulding snugly around pipe penetrations.

In the symphony of materials that compose a resilient roof vent termination, choosing the right rubber and sealants is akin to selecting the perfect brush for a painter—vital for a flawless finish. When combined with metal or plastic components, these sealants ensure your roof remains a sanctuary against the elements, year after year.

Installation Best Practices for Roof Vent Termination

Proper Placement and Positioning

In the silent symphony of a well-ventilated roof, the placement of the roof vent termination plays a pivotal role. It’s not merely about fixing a cap atop your roof but understanding the intricate dance between air movement and architectural integrity. Proper placement ensures that moisture escapes efficiently, preventing the insidious creep of mould and decay that can threaten the very soul of a home.

Strategic positioning often involves considering the prevailing wind patterns and the specific design of the roof. For optimal performance, the roof vent termination should be installed at the highest point, free from obstructions that could impede airflow. This mindful placement creates a natural draft, harnessing gravity and wind to facilitate continuous ventilation.

Sometimes, the simplest details make the difference. For instance, ensuring that the vent is away from dormers, chimneys, or other roof penetrations can prevent backdrafts or air leaks. To achieve this, many experts recommend following a few core principles:

- Maintain a minimum clearance from roof ridges or peaks

- Position the vent termination at least 300mm above the roof surface

- Ensure the vent cap is free from debris and properly sealed

Ultimately, the installation of a roof vent termination is an act of balancing function and form—each decision affecting the longevity and health of the entire structure. Proper placement isn’t just about compliance; it’s about respecting the unseen forces that keep a home alive and breathing.

Sealing and Waterproofing Techniques

Sealing and waterproofing your roof vent termination isn’t merely a task; it’s an act of safeguarding the very essence of your home’s integrity. Inadequate sealing invites moisture, which can silently erode the structure from within, undermining years of craftsmanship. The goal is to create a barrier—impermeable yet accommodating of airflow—so that the delicate balance between ventilation and protection is maintained.

Using high-quality sealants designed specifically for roofing applications is essential. These materials must withstand the harshest weather conditions without cracking or degrading over time. When installing the roof vent termination, ensure that the flashing is properly sealed to prevent leaks. Sometimes, a combination of butyl tape and specialised sealant provides an extra layer of defence, especially around complex roof penetrations.

For optimal waterproofing, consider the following core principles:

- Ensure all joints and seams are thoroughly sealed with weather-resistant materials.

- Apply sealant generously around the base of the vent cap and flashing edges, pressing firmly to eliminate air pockets.

- Regularly inspect the roof vent termination for signs of wear or damage, resealing as necessary to maintain waterproof integrity.

Remember, the true challenge isn’t just in installing a roof vent termination but in respecting and reinforcing the unseen forces that protect your home. Proper sealing and waterproofing are the silent guardians, standing between your sanctuary and the relentless assault of nature’s elements.

Tools Required for Installation

In the intricate dance of roof vent termination, precision and care are paramount. Every tool employed becomes an extension of craftsmanship, guiding the seamless integration of ventilation with the integrity of your roof. The right tools transform a routine task into an act of artistry—ensuring longevity and effectiveness.

Essential for a flawless installation are a high-quality drill, a utility knife, a caulking gun, and a torque wrench. These instruments serve as your trusted allies, enabling meticulous sealing and secure fastening. When working with metal or PVC roof vent termination components, specialised cutting tools and metal snips become indispensable to achieve clean, accurate cuts that fit perfectly and seal tightly.

For optimal results, follow a systematic process: first, accurately mark the placement of the vent; then, carefully cut the opening, ensuring sharp precision. Next, secure the flashing and vent cap with corrosion-resistant fasteners, taking care to tighten without overexerting—lest you compromise the seal. Remember, the goal is to create a barrier that stands resilient against the elements, a shield forged not only by materials but also by skilled application.

Safety Tips During Installation

In the realm of roof vent termination, safety is not merely a precaution but the foundation upon which all craftsmanship stands. As the sun casts its relentless gaze and the wind whispers secrets through the shingles, each step must be undertaken with unwavering vigilance. Harnessing the correct safety tips during installation transforms a potentially hazardous task into a symphony of precision and care.

First, always employ a sturdy harness and secure ladder placement—stability is paramount when working atop a pitched roof. Falling debris or sudden gusts can threaten even the most experienced installer. Keep your workspace organised, with tools and materials within arm’s reach, minimising distractions and hurried movements. Remember, a focused mind and steady hand forge the pathway to a flawless roof vent termination.

To further bolster safety and efficiency, consider this ordered approach:

- Inspect the weather forecast—avoid installation during high winds or rain.

- Wear appropriate personal protective equipment, including gloves, eye protection, and non-slip footwear.

- Mark the vent placement meticulously, ensuring correct alignment and positioning.

- Secure your ladder on a level surface, checking stability before ascending.

By embracing these practices, the installation of roof vent termination becomes a harmonious act—one that honours both the integrity of your roof and the safety of those who undertake it. Every bolt tightened and seal applied echoes with the craftsmanship that elevates a routine task into an enduring testament of skill and care.

Common Issues and Troubleshooting

Leaks and Water Intrusion

Water intrusion caused by faulty roof vent termination is a surprisingly common issue that can quietly wreak havoc on a building’s structure. When vent caps or flashing are improperly installed or deteriorate over time, leaks often follow. These leaks not only compromise the roof’s integrity but can also lead to mould growth and costly repairs.

Troubleshooting such leaks begins with a thorough inspection of the vent termination area. Look for signs of cracks, corrosion, or gaps in the flashing. Sometimes, the problem lies with inadequate sealing around the vent cap, permitting water to seep in during heavy rain. In these cases, replacing or resealing the roof vent termination components can resolve the issue.

In more persistent cases, water may infiltrate through poorly positioned or damaged vent pipes. Addressing these issues requires a keen eye for detail and a solid understanding of waterproofing techniques, ensuring that your roof vent termination remains secure and watertight for years to come.

Blockages and Debris Buildup

Blocked roof vent termination is a common culprit behind poor ventilation and moisture buildup in roof spaces. Debris such as leaves, twigs, or even nests can clog the vent, restricting airflow and causing excess humidity. Over time, this buildup can lead to mould growth, rotting wood, and compromised structural integrity. Regular inspection is vital to catch these issues early.

In many cases, the first sign of blockage is reduced airflow or strange odours emanating from the roof. To troubleshoot, start by removing any visible debris and checking for damage to the vent cap or flashing. Sometimes, the problem lies deeper, with dirt or nesting materials lodged inside the vent pipe itself. Using a garden hose or compressed air can help clear minor blockages.

- Remove accumulated debris from around the roof vent termination.

- Inspect the vent cap and flashing for cracks or corrosion.

- Ensure the vent pipe is clear of obstructions using appropriate tools.

Ignoring these issues can lead to reduced performance and costly repairs. Proper maintenance of the roof vent termination is essential to keep your ventilation system functioning optimally and prevent moisture-related problems from taking hold.

Corrosion and Material Deterioration

Corrosion and material deterioration pose a silent threat to your roof vent termination, quietly undermining its integrity over time. Metal components, especially those exposed to the elements, are vulnerable to rust and decay—copper and steel are no exception. When corrosion takes hold, it can cause cracks, holes, or loose fittings, leading to potential water intrusion and compromised ventilation.

In some cases, the deterioration isn’t immediately visible, hiding beneath layers of paint or debris. Regular inspections are crucial. Look for signs such as discolouration, flaking paint, or a rough texture on the vent cap and flashing. Over time, these symptoms can escalate into more serious issues, including leaks or complete failure of the roof vent termination.

- Corroded metal parts

- Cracked or broken vent caps

- Loose or missing flashing

Addressing these problems promptly prevents costly repairs and ensures your roof’s ventilation remains effective. Material deterioration is insidious, but vigilance and timely intervention preserve the longevity of your roof vent termination and keep moisture at bay.

Improper Venting and Ventilation Issues

Even the most meticulously installed roof vent termination can fall prey to common issues that threaten its efficacy. Improper venting, for example, is a silent saboteur—causing moisture build-up, mould growth, and reduced airflow. When ventilation is compromised, your roof becomes a humid battleground, risking structural damage and increased energy costs.

Blockages and debris accumulation are equally insidious. Leaves, dirt, and small critters can clog up the vent cap or screening, creating a veritable fortress for moisture and mould. Regular inspections are the only defence against these nuisances. Sometimes, the problem isn’t immediately obvious; a vent that looks pristine on the surface might be harbouring unseen obstructions within.

Addressing these issues swiftly ensures your roof vent termination continues performing optimally. Remember, a well-maintained vent not only promotes good airflow but also safeguards the longevity of your entire roofing system. When venting issues are left unchecked, the consequences—ranging from minor leaks to catastrophic roof failure—are hard to ignore. Vigilance in troubleshooting is, after all, the key to a roof that breathes as it should.

Maintenance and Inspection of Roof Vent Terminations

Regular Inspection Routines

In the realm of maintaining a fortress’s integrity, the importance of regular inspection routines for roof vent termination cannot be overstated. These vital components serve as the guardians against water intrusion and pest infiltration, yet they are often overlooked until a problem emerges. A diligent eye on their condition ensures longevity and optimal airflow within the roofing system. Imagine a silent sentinel, standing guard against the relentless forces of nature—such is the role of a well-maintained roof vent termination.

Periodic inspections should include a thorough visual assessment, checking for signs of corrosion, cracks, or displaced flashing. Equally significant is the removal of debris that can obstruct airflow or cause moisture build-up. For those overseeing multiple installations, an ordered checklist can streamline the process:

- Examine the vent cap for damage or blockages.

- Inspect flashing for corrosion or gaps.

- Ensure sealing materials remain intact and effective.

- Look for signs of water pooling or leaks around the vent base.

Maintaining a routine schedule not only prolongs the life of the roof vent termination but also fortifies the entire roofing structure against the unpredictable whims of weather and time. Remember, proactive care is the key to preserving the sanctity of your building’s crown—its roof vent termination.

Cleaning and Debris Removal

Keeping your roof vent termination in pristine condition isn’t just about aesthetics; it’s essential for the longevity and efficiency of your roofing system. Regular cleaning and debris removal play a vital role in preventing blockages that can lead to moisture build-up and potential water intrusion. Over time, leaves, dirt, and even small twigs can accumulate around the vent cap, obstructing airflow and creating a breeding ground for mould and pests. A simple but consistent maintenance routine can make all the difference in safeguarding your property.

To ensure optimal performance, it’s advisable to inspect your roof vent termination at least twice a year—preferably during seasonal transitions. When doing so, look out for signs of corrosion or damage to the vent cap and flashing. Removing debris is straightforward; use a soft brush or cloth to clear away buildup. For those overseeing multiple properties, an ordered checklist can streamline this process:

- Examine the vent cap for damage or blockages.

- Clear away accumulated debris around the vent opening.

- Check the flashing for corrosion, cracks, or gaps.

- Ensure sealing materials remain intact and effective.

Consistent attention to your roof vent termination not only preserves its integrity but also promotes proper ventilation, helping your building breathe easier and stay protected against the elements. After all, a well-maintained roof vent termination is a silent guardian, quietly defending your home or business from water damage and pests with every inspection.

Replacing Damaged Components

Maintaining the integrity of your roof vent termination isn’t just about routine checks; it’s an essential safeguard against costly damage. Over time, components can suffer from wear and tear, leading to compromised ventilation and potential leaks. Regular inspections help identify early signs of deterioration, allowing for timely intervention before minor issues escalate into major repairs.

When inspecting your roof vent termination, pay close attention to damaged or corroded parts. Damaged vent caps, cracked flashing, or deteriorated sealants can all undermine the system’s effectiveness. Replacing these components promptly ensures your roof remains watertight and properly ventilated. For efficiency, consider creating an ordered checklist such as:

- Inspect the vent cap for damage or corrosion.

- Examine the flashing for cracks or gaps.

- Replace worn or broken sealants around the vent opening.

- Ensure the vent remains securely fastened to prevent movement or dislodgement.

Addressing damaged components swiftly preserves the longevity of your roof vent termination and maintains optimal airflow. Neglecting these repairs can lead to blockages, moisture accumulation, and even pest ingress—silent threats to your property’s structural health. Regular maintenance isn’t just maintenance; it’s a vital act of stewardship for your building’s long-term resilience.

Legal and Building Code Considerations

Local Building Codes and Regulations

In the intricate dance of architecture and regulation, understanding the legal and building code considerations surrounding roof vent termination is paramount. It’s a silent guardian of safety and efficiency, yet many overlook its significance until a problem arises. Local building codes are more than just bureaucratic hurdles; they are the moral backbone that ensures structures withstand the test of time and elements.

Compliance with these codes isn’t optional — it’s an ethical obligation to protect inhabitants and property alike. Different jurisdictions often have nuanced regulations concerning the height, placement, and materials of roof vent termination. Ignoring these can result in costly fines, structural failures, or compromised ventilation systems.

To navigate this complex landscape, professionals often reference authoritative guidelines, such as

- local building authorities

- manufacturer specifications

- industry standards

. These serve as the compass to ensure that every roof vent termination adheres to safety, functionality, and legality, safeguarding both the builder’s integrity and the home’s longevity.

Permits and Inspections

In the realm of construction, the significance of adhering to legal and building code considerations cannot be overstated when it comes to roof vent termination. These regulations serve as the foundation for ensuring safety, durability, and functionality. Ignoring permit requirements or inspection protocols can lead to unforeseen costs or, worse, structural vulnerabilities that threaten lives and properties. Compliance with local building codes is not merely bureaucratic red tape; it is a moral imperative that safeguards the integrity of your project.

Most jurisdictions mandate specific permits before installation, which often involve detailed inspections to verify adherence to safety standards. During these inspections, authorities scrutinise aspects such as the placement, height, and material quality of the roof vent termination. To streamline this process, many professionals compile documentation referencing industry standards and manufacturer specifications, ensuring every component aligns with legal expectations.

- Securing the appropriate permits

- Scheduling inspections at critical project milestones

- Documenting compliance with local regulations

Failing to navigate this legal landscape can result in costly fines or, more critically, compromised ventilation systems that jeopardise structural health. The pursuit of perfection in roof vent termination, therefore, becomes an act of moral responsibility—one that intertwines craftsmanship with legality, ensuring that every home withstands not only the elements but the tests of time.

Environmental Considerations

Legal and building code considerations are the backbone of safe, durable, and efficient roof vent termination. Overlooking these regulations can result in costly fines or, worse, compromised ventilation systems that threaten structural integrity. Building codes are designed not just to comply with bureaucratic mandates but to uphold safety standards that protect lives and property. Adherence ensures that your roof vent termination aligns with local regulations, promoting long-term performance and safety.

Environmental factors also play a pivotal role in the selection and installation of roof vent termination. Proper placement can reduce the risk of water intrusion, minimise debris accumulation, and prevent corrosion. For example, situating vents away from prevailing wind directions can prolong their lifespan and optimise airflow. Moreover, choosing materials such as corrosion-resistant metals or UV-stable plastics can mitigate environmental wear and tear. Remember, a robust roof vent termination isn’t just about functionality; it’s about harmonising with the environment to foster sustainability and resilience.

Choosing the Right Roof Vent Termination for Your Roof

Factors to Consider

Choosing the right roof vent termination is essential to ensure optimal ventilation and protect your home from water intrusion. An effective roof vent termination not only facilitates proper airflow but also guards against the elements, preventing leaks and debris from entering the vent system. When selecting a vent termination, consider the material compatibility, as options range from durable metals like aluminium and copper to weather-resistant plastics and PVC. The environmental exposure your roof faces—such as high winds, heavy rain, or snow—should also influence your choice.

Furthermore, the position of the roof vent termination plays a pivotal role in its performance. Ideally, it should be installed away from potential sources of water pooling or debris accumulation. Often overlooked, the importance of a well-designed vent cap or specialised vent terminal cannot be overstated; these components enhance the longevity of your ventilation system by providing additional protection against corrosion and blockage. Ultimately, meticulous attention to these factors can significantly extend the lifespan of your roof vent termination and ensure it functions flawlessly for years to come!

Professional Consultation

Choosing the right roof vent termination can make all the difference in maintaining a healthy, efficient roofing system. When considering a professional consultation, it’s crucial to evaluate how the vent will integrate with your existing roof structure and climate conditions. An experienced roofing specialist can assess factors such as material compatibility, environmental exposure, and the specific type of roof vent to ensure optimal performance.

Expert guidance also ensures compliance with local building codes and regulations, which can vary significantly. A professional will recommend the most durable and weather-resistant options—such as aluminium or copper—that withstand high winds, heavy rain, and snow. They can also advise on the ideal placement of the roof vent termination to prevent water pooling or debris accumulation, maximising longevity and functionality. Remember, investing in a proper roof vent termination with expert help is an essential step toward safeguarding your home’s ventilation system for years to come!

Cost vs. Durability

Choosing the right roof vent termination is a balancing act between cost and durability—an equilibrium that can make or break your roofing system’s longevity. While budget-friendly options like plastic or PVC might initially seem appealing, they often falter under harsh weather conditions, leading to costly repairs down the line. Conversely, materials such as aluminium or copper may command a higher upfront investment but offer remarkable resilience against the elements, reducing the need for frequent replacements.

It’s worth considering that a superior roof vent termination not only withstands wind, rain, and snow but also maintains optimal airflow, preventing moisture buildup and ensuring your home breathes easy. When evaluating options, ask yourself: will this vent termination stand the test of time or become a recurring expense? Sometimes, spending a little extra now can save a great deal of trouble later—making durability worth every penny.

0 Comments